Cat® Certified Rebuild by Avesco

Take advantage of the extra value built into your Cat® equipment. The Cat Certified Rebuild Programs return your end-of-life machines, systems and components to like-new condition at a fraction of the cost of buying new.

A rebuild changes out all major machine components and most minor ones, too. The result is equipment that performs like new, priced at a fraction of the cost.

REBUILD OPTIONS

—

Return your entire machine to good-as-new condition — or better-than-new with upgrades and enhancements.

Bring the heart of your machine — including radiator, engine, transmission, torque converter, final drive and axle — back to new.

Avoid the cost and downtime of individual repairs by bringing your excavator’s pumps, motors, valves, accumulators, hoses, tubes, tanks, coolers and cylinders back to new.

Breathe new life into key components like Cat machine engines, transmissions, torque converters, axle assemblies, differentials and final drives.

Restore your marine propulsion engine, generator set, pump, locomotive or other power system to its original performance and durability levels.

From single component to complete machine options, we've got you covered!

A rebuild is often most advantageous when your equipment has several issues that need attention. It gives you the chance to replace or restore multiple systems, along with upgrading the machine's performance and appearance.

A Cat Certified Rebuild follows 10 steps

—

1. Inspection / Evaluation

A machine rebuild includes 350 tests and inspections, while a power train rebuild includes 200 tests and inspections. A customized plan and cost estimate for the rebuild are provided.

2. Disassembly

The machine and power train are completely disassembled. A machine rebuild includes the replacement of 7,000 parts, while a power train gets 3,000 new parts.

3. Reconditioning

During this step, frames are straightened, welded & reinforced; new linkage pins and shaft bearings are installed; hydraulic systems are restored and electronic controls and software are replaced.

4. Engineering Updates

Rebuilt machines receive the latest improvements in safety, performance, comfort and maintenance.

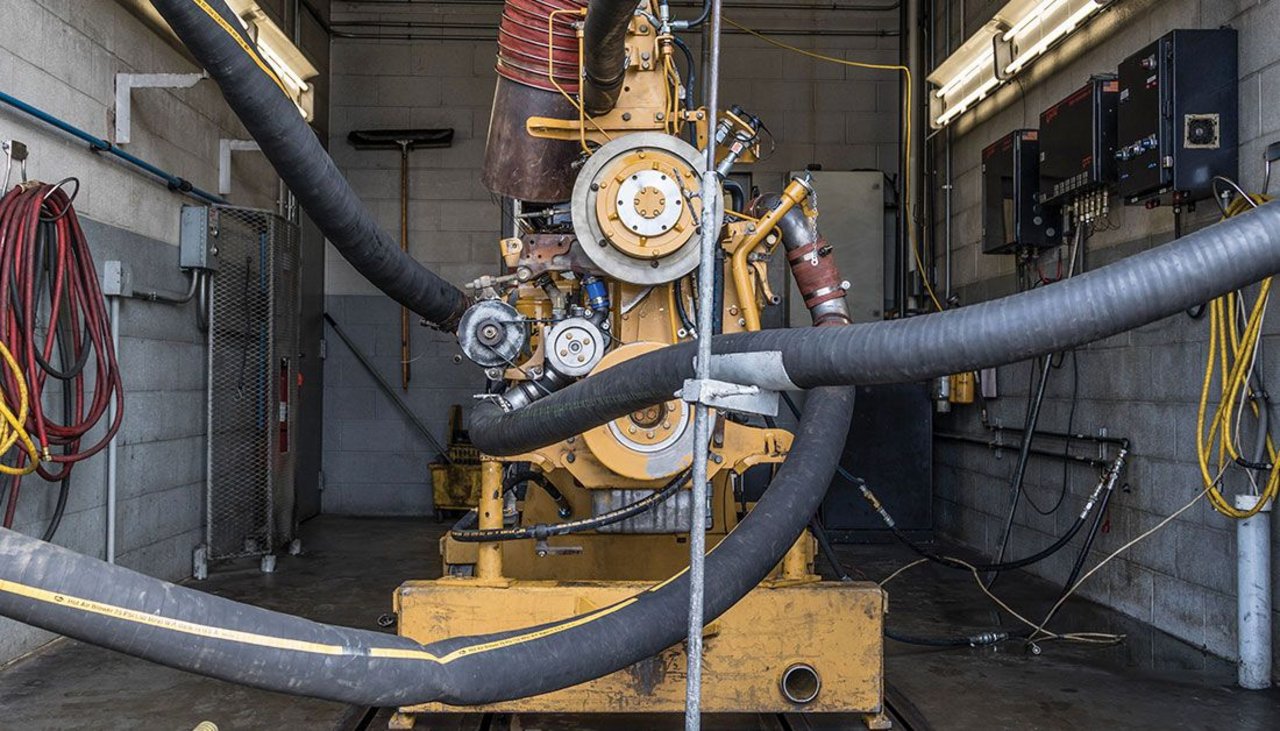

5. Power Train Tests

The engine, fuel system, transmission, torque converter, differential, final drives and radiator are reconditioned, updated, tested and reinstalled.

6. Reassembly

Critical torques, clearances and pressure settings are maintained and recorded and the engine wiring harnesses are replaced.

7. Performance Testing

This step ensures quality control through instrument and operational testing. Contamination control procedures are strictly adhered to during this process.

8. Repainting

The rebuilt machine receives new paint, model identity graphics and a Cat Certified Rebuild decal.

9. New Serial Number or Product Identification Number

This new number identifies the machine and entitles it to a like-new standard warranty. This step also enables a higher resale value for the machine.

10. Customer Evaluation

The rebuild is not officially complete until the owner is satisfied. The machine is put to the test in a working environment, where it is evaluated by the owners and operators.

Rebuild Pros | Rebuild Cons |

|

|

REQUEST FOR MORE INFORMATION

—

For more information please contact our representativeS:

| Estonia +372 679 9260 | info.ee@avesco-cat.com | Latvia +37125639614 | info.lv@avesco-cat.com | Lithuania +370 52 603 242 | info.lt@avesco-cat.com |