How to choose a skid steer loader

It should be noted that name “loader” does not accurately reflects the specifics of this machine. In turn, this piece of engineering equipment has excellent technical properties and is an extremely versatile machine suitable for most applications. Skid steer loaders are fitted with accessories such as pallet forks, brushes, snow removal equipment, hydraulic hammers, soil drills, concrete or asphalt cutters, grass trimmers, brush cutters, soil aerators, vibratory plates and other equipment that make the mini loader multifunctional and save you money. Therefore, the skid steer loader can be used year-round and every day.

Although skid steer loaders are quite small, they are much more manoeuvrable than other machines of the same purpose. Therefore, it is obviously impossible to provide a universal recipe for choosing a skid steer loader. Different models work differently under different conditions; some loader models do one type of job better, others excel at a different type of job.

A LITTLE BIT OF HISTORY

Now to understand full capabilities of this machine, let’s talk about what a skid steer loader is and how it came about. The interesting fact is that the first skid steer loader was made to transport turkey manure out of a barn. In 1956, a Minnesota turkey farmer appealed to brothers Louis and Cyril Keller, the famous inventors and technical innovators of the time, to develop self-propelled machinery for transporting manure. A few months later, a three-wheeled prototype of a skid steer loader already appeared on the farm. The technical literature describes the skid steer loader as a versatile, compact machine for working indoors, on narrow city streets, in factory areas, warehouses, docks, ship decks, etc. The left and right wheels are powered by separate axial piston type hydraulic motors that can operate in opposite rotation mode, allowing the skid steer loader to rotate at a single point.

WHERE TO START?

When choosing this special machine, it is important to choose only the most efficient skid steer loader, which has one main task – to achieve the required performance with minimal operating costs. In this case:

1. First, determine what works you need the new mini wheel loader for.

2. Next, analyse the types of loaders that dominate the market, their equipment, advantages and disadvantages in implementing the desired job execution plans.

3. After analysing these criteria, you can move on to the specific model of a skid steer loader based on its specifications. We will look into Cat® skid steer loaders specifications for obvious reasons.

IDENTIFY YOUR NEEDS

First, let’s find out the needs that the loader must meet. This may include work in construction, agriculture or maintenance and repair of roads and sidewalks, etc. If you need to have a multifunctional machine that could do most jobs, the best option is a loader with the widest range of interchangeable attachments. For example, in agriculture the primary function of a skid steer loader is to replace manual labour. Because of the wide range of attachments they can handle compound feedingstuffs, hay, straw, displace manure, and do other work.

Skid steer loader allows much faster loading of feedingstuffs into the dispenser than manually. In this case, cows are fed more quickly, which results in more feedingstuffs being eaten and increased milk yield per day. The increase in milk yield is very significant as it allows you to recoup the cost of purchasing a skid steer loader and generate additional net profits in the future. But that’s just one of the many tasks a skid steer loader can do on the farm. Besides this, skid steer loaders can be actively used to keep any yard clean – sweeping and collecting debris in summer, and removing snow in winter. In addition, even such attachments as excavator equipment, screw drill, brush cutter, stump shredder can be fitted depending on the operation of the loader’s hydraulic system. The skid steer loader is also useful on tree nursery farms, as it makes transplanting trees and shrubs much easier.

Cat D3 series Skid steer loaders and Multi terrain loaders at work

ANALYZING MAIN CRITERIAS OF SKID STEER LOADERS

The wide range of skid steers, that available on the market, will make it difficult to find a skid steer that fully meets your needs and requirements. Therefore to implement 2nd task we suggest you evaluate a number of criteria to help you make the right choice according to your needs:

- lift capacity of the loader;

- engine power;

- convenient service;

- machine dimensions;

- cabin comfort;

- range of attachments.

Lift capacity.

Determine the necessary amount of load for your loader by selecting it with some margin. For example, if you suddenly need to lift or carry a load, which is heavier than calculated, the “reserve” will not both save you from accidents, and also help prevent the loader from operating at full capacity. Frequent operation at full capacity reduces the life of the skid steer loader and endangers its technical condition. In addition, if on-farm work requires constant movement (driving) and the time factor is critical, then consider the transport speed of the skid steer loader when choosing.

Engine power value.

If the newly acquired skid steer loader will be used with additional equipment / attachments then you will need additional 30 - 40 percent of engine power. Engine power is a very important indicator if the skid steer loader has to work with high load and at the same time power an attachment. In addition, efficient speed of the turn arounds greatly depends on the engine power value.

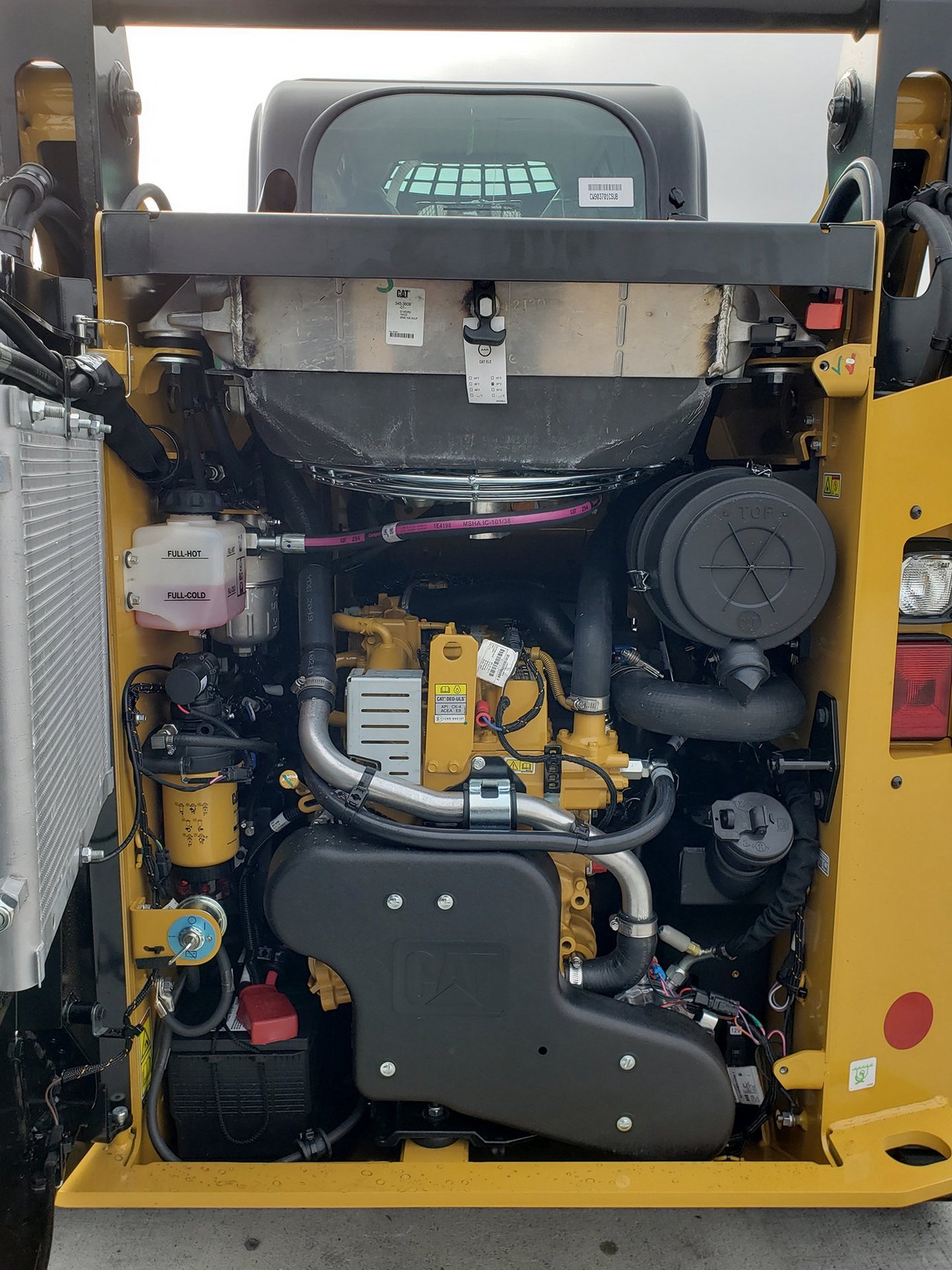

Convenient service.

When operating the skid steer loader, the operator will need to perform daily maintenance (DM), which includes external inspection of the loader, visual inspection of connections of all important units, cleaning and washing operations, refuelling loader, checking coolant and grease levels. Liquids should be refilled as needed. That’s why the ease of lifting the bonnet and easy access to the main service points of the loader are essential for convenient and fast daily maintenance. Besides, easy access to the fuel pump, generator, fuel/air filters and other units is also very important during repair works.

A comfortable workplace.

The worker who works with the loader must be given the most comfortable working space and therefore certain aspects need to be considered:

- easy access and egress from the cab;

- noise reduction;

- presence of a heating system;

- air circulation in the cab;

- seat comfort and ergonomic layout of controls;

- easy operation;

- good cab visibility; bucket visibility while the truck is in operation.

Dimensions.

When choosing a skid steer loader, focus on the features that are most important for performing specific tasks. Depending on the size and manoeuvrability of the skid steer loader, the choice should be based on the operating conditions. For example, maximum load capacity may be the priority for one company, whereas it may be agility and the ability to move in a small warehouse or cramped spaces for another. If you work in areas where the manoeuvrability of the loader is paramount, it should be smaller in size, but the lift capacity will be correspondingly lower as well. Besides, determine the working surface on which the loader will work. If the surface of the area where the loader is to be operated is covered with gravel or other poor quality road surface material, then make sure you get larger diameter wheels when purchasing the loader.

Attachments.

A standard skid steer loader comes with a front bucket, but very often companies and farms make additional choices for pallet forks. The wide range of interchangeable attachments allows the skid steer loader to be turned into a multifunctional machine, while the quick-connect mechanism allows all attachments to be replaced in the shortest amount of time. It is important to understand here that any interchangeable attachment will overload the machine’s hydraulic system, so when selecting a new skid steer loader, you must make provision for hydraulic power reserves for optional equipment.

Besides all the criterias, we would like to stress out, that modern skid steer loaders work under increased load conditions, which places special demands on the quality of maintenance and the frequency of servicing. Often times, relatively cheap equipment from little known manufacturers is completely devalued due to the complexity of maintenance, the search for spare parts and the long waiting periods. In order to avoid unnecessary costs, it is recommended to purchase only well-known brands of loaders, which will be serviced by an extensive network of service centres. For example, Avesco offers professional, high quality Cat construction machinery, serviced by experienced, highly skilled mechanics. If you find it too difficult to decide which loader would be the best choice for you, just consult with the technicians selling the equipment and they will give you some really useful tips.

NEW GENERATION CAT® D3 SERIES SKID STEER LOADERS: WHAT'S NEW

New generation Cat® skid steer loaders are designed and developed by “Caterpillar”. Wide range of skid steer loaders can solve problems of various complexity and provide:

- easy access to maintenance units;

- easy maintenance and repair;

- the ability to extend the scope of application by a wide range of accessories;

- spacious, comfortable and ergonomic operator cab.

The official dealer of Cat® equipment in the Baltics Avesco currently offers 8 models of Cat® skid steer loaders. All of these models are fitted with airtight cabs, which provide the operator with a cleaner and quieter working environment, and excellent visibility during operation.

joysticks, there is plenty of legroom,

operator’s seat has air suspension, it is heated and

equipped with forced ventilation, making it

comfortable to use throughout the day.

efficient!

Cab. New Cat® skid steer loader cab provides maximum operator safety and comfort. The excellent sound insulation of the D3 Series makes work not only more enjoyable, but also more efficient – the operator is less tired, the work is faster, more accurate and productive. The airtight, spacious and ergonomic cabin of seamless design creates a clean and quiet environment. Air conditioning and a seat with air suspension and a high back rest, faux leather or fabric finish combined with panoramic views provide great comfort. In addition, the seat slides along with the joysticks for increased ergonomics and easier control of operations of the skid steer loader.

All D3Series models are fitted with adjustable joystick controls on the seats as standard to ensure operator comfort. The skid steer loader control components include an operation control lever mechanism which allows starting the motor only when both levers are lowered. Lifting of this mechanism blocks the controls and stops the engine. In addition, these two levers act as armrests for the operator and reduce the fatigue of the operator operating the loader for extended periods.

The hydraulic system ensures maximum power and reliability of the skid steer loader. Cat® D3 model skid steer loaders feature high-performance powertrain and advanced “High Flow” hydraulic system. High capacity is ensured by the electronic torque control system. This system can be used when maximum hydraulic tool performance is required. All D3 series models feature larger lifting cylinders for 19 percent more lift capacity. Hydraulic pumps are driven directly from the engine, which allows for maximum equipment performance and reliability. These trucks feature radial piston hydraulic motors that are significantly more efficient than other types of hydraulic motors.

High performance cooling system. The performance of the cooling system on D3 models has been improved by using a parallel cooling system and hydraulic cooling fans. In this case, the high-performance hydraulic oil cooler increases machine life and allows work to be carried out with higher loads, increased ambient temperature and long use of additives. The high-performance hydraulic cooling fan is efficient even at high loads. In addition, choosing a variable speed fan reduces fuel consumption, increases machine performance, reduces noise and increases machine efficiency during the cold season.

Leveling system. These mini loaders are equipped with an intelligent leveling system “Intelligent Leveling” (ILEV), which maintains the set angle during lifting and automatically returns the implement to the digging position when lowered.

Control. In fact, the Cat® skid steer loader controls are a bit like a video game. It also requires quick reaction and skill to use controls quickly and properly. The skid steer loader is controlled by two joysticks. The left joystick is responsible for movement and the right joystick – for bucket control. With this type of control, the movement of the skid steer loader is completely controlled by the left joystick. However, hand movements should be smooth, fast, but not sudden. It should be noted that the multifunction display can be used to change the sensitivity of the joysticks and the aggressiveness of the machine. As a result, the machine will be adaptable to both the experienced operator and the newcomer. The joysticks are equipped with additional control buttons. For example, pressing a button can set the float position, start the operation of replaceable attachments, etc.

Convenient service. Simplicity and ease of service significantly reduce the downtime of the skid steer loader. In this case, the unique and quick lifting of the Cat® D3 cab provides easy access to the service points: the cooling system, all hydraulic pumps, electric motors, valves, circuits and the hydraulic tank. For example, the engines in these skid steer loaders can be accessed and serviced by opening the tailgate. Raising of the other cover reveals the radiators of the engine coolant and hydraulic oil coolant, which are evenly cooled by the fan.

One of the key service points to keep in mind is the ease of servicing the engine. The fuel and oil filters and the oil level gauge are visible on the left side of the engine, but the measurement will not be accurate if done immediately after switching off the engine. In this case, the oil level gauge will indicate that there is not enough oil because too little time has passed for all the oil to flow into the crankcase. It is best to measure before starting a cold engine, but in this case, make sure the skid steer loader is in horizontal position. On the same side there is a screw-in cap of the oil filler opening. On the left side of the engine there is also battery, coolant expansion tank, and on the right side – the engine air filter. Such arrangement and accessibility speeds up its service and increases its reliability.

in the operator’s cockpit is located on

the bonnet that is opened (left in the picture).

Engine. D3 series skid steer loaders feature Cat® brand diesel engines that deliver excellent performance and torque (see specification table below). Modern diesel engines are economical and powerful. The engines used in the skid steer loaders are developed by engineers for longer and uninterrupted operation. Unlike many stereotypes, they are eco-friendly and make little noise. It also consumes significantly less fuel than previous models –30 percent lower fuel consumption. This is explained by the high pressure in the combustion chambers, the design of the engine, its operating principle and several other factors.

| Loader model | 232 D3 | 226 D3 | 236 D3 | 242 D3 | 246 D3 | 262D3 | 272 D3 | 272 D3XE |

|---|---|---|---|---|---|---|---|---|

| Engine | Cat 2,2 CRDI | Cat 2,2 CRDI | Cat 3.3B DIT | Cat 3.3B DIT | Cat 3.3B DIT (turbo) | Cat 3.3B DIT (turbo) | Cat C3.8 DIT (turbo) | Cat C3.8 DIT (turbo) |

| Power, KW/HP | 50.1/67.1 | 50.1/67.1 | 55.4/74.3 | 55.4/74.3 | 55.4/74.3 | 55.4/74.3 | 73.0/98.0 | 73.0/98.0 |

| Operating weight, kg | 2653 | 2955 | 2879 | 3238 | 3392 | 3763 | 1570 | 1680 |

| Lift capacity, kg | 705 | 856 | 820 | 1000 | 1000 | 1225 | 4143 | 4342 |

MAIN FEATURES AND ADVANTAGES OF CAT D3 SKID STEER LOADERS

For more information about Cat® skid steer loaders and how to choose it for your business needs, please contact our representative:

in Estonia: info.ee@avesco-cat.com

in Latvia: info.lv@avesco-cat.com

in Lithuania: info.lt@avesco-cat.com