HOW TO EXTEND THE LIFE OF AN UNDERCARRIAGE

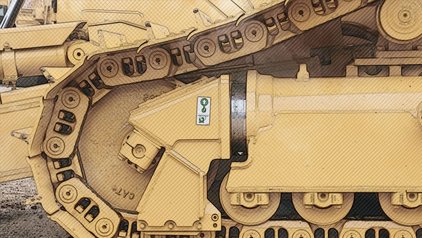

Undercarriage typically represents an average 50% of a machine’s owning and operating costs, so it makes sense to invest in a system that will deliver the most value. Every Cat® undercarriage is designed by Caterpillar engineers and built to exacting specifications to match your machine and application — and deliver the lowest operating costs.

| OUTLASTS COMPETITORS Because Caterpillar manufactures its own undercarriage, every component meets strict specifications and quality standards that no competitor can match. Durable, reliable components result in lower operating costs. | PROVEN PERFORMANCE Cat undercarriage is factory and field tested. Tests have shown that Cat undercarriage delivers up to 2X the life of competitive undercarriage. |

| DESIGNED FOR YOUR APPLICATION Cat engineers understand how application demands wear undercarriage components. They design undercarriage as a system. Each one is built to take on specific conditions such as sand, gravel, mud and clay. | BEST RETURN ON INVESTMENT With longer wear life and lower cost per hour than competitive brands, Cat undercarriage delivers the best return on your investment. And, Cat Undercarriage Assurance offers you the best protection in the industry for the lowest total cost of ownership. |

HOW TO EXTEND THE LIFE OF AN UNDERCARRIAGE

—

Proper use of the machine can extend the life of the undercarriage.

- Side-hill operation can accelerate wear on the links on one side when overused.

- Avoid unnecessary reverse operation. It wears bushings and sprockets.

- Check the track alighment. When tracks are not properly alighned it can cause component wear.

- Minimize sharp turns and counter-rotations, as these maneuvers stress the tracks from brake use on one side or the other.

- Slipping the track can cause premature wear on components and the track itself. It also reduces production and increases fuel consumption.

- Keep the right track tension. Adjust and test the track tension as needed. Tight tracks can increase wear on bushings, sprockets, links and idlers. Too tight of tracks can increase wear and strain.

- Choose the right shoes for the job. Using the wrong shoe width can increase wear and strain on links pins and bushings.

- Keep the undercarriage clean. Materials and debris can build up, especially in certain climates and depending on what type of material the machine is working in.

- Avoid high speed tracking, as it elevates track temperature too high and causes premature wear.

An operator should be ultra-tuned into the machine. How it looks, how it sounds and how it reacts can help detect problems. The physical aspects, along with how the operator runs the machine, can make the difference in extending the life and savings tens-of-thousands of dollars. The flip side is reducing the life and needing to replace components earlier, make extra fluid changes, break components, or worse, replace the entire undercarriage on the machine.

For more information please contact US:

| Estonia +372 679 9260 | info.ee@avesco-cat.com | Latvia +371 2 570 17 11 | info.lv@avesco-cat.com | Lithuania +370 52 603 242 | info.lt@avesco-cat.com |